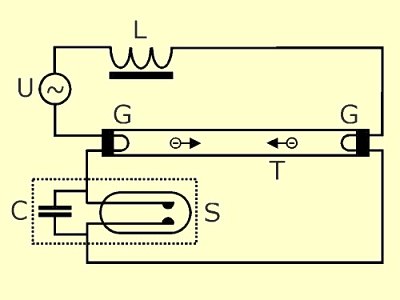

TL starter

AUTOMATIC-IGNITION

An automatic ignition method that used a

combination of inductive ignition and

pre-heating of the electrodes, could be

found in tube lights (TL) and in TL based

sunlamps. Tube lights were commonly

started with a specially designed

automatic starter consisting of a small

neon glow discharge tube S and a

capacitor C. When switched on in a cold

position the full supply voltage U of (in

Europe) 230 volts AC was applied to the

gas discharge tube S of the starter

through the coil L and the two filaments

G. This caused a glow discharge in the

starter for which the coil and the two

filaments formed the current limiting

ballast. Due to the resistance of the coil

and the filaments the voltage over the

starter dropped to about 200 volts. Since

the current was still relatively small, the

filaments were hardly heated and most of

the time there was no glow discharge yet

in the tube light itself. This situation would

not alter if not one of the electrodes of

the starter was constructed as a bi-metal,

a metal strip that bended when it was heated.

The bi-metal electrode was positioned in such a way that it came in touch with the

other electrode when it bended over due to the heat of the glow discharge in the

starter, causing a complete short circuiting of the starter. The short circuit current

was only limited by the coil and the two filaments and it was large enough to make the

filaments at both ends of the tube light glow. Since the short circuiting of the starter

also terminated the glow discharge within the starter, the bi-metal electrode cooled

down and straightened again until it came loose from the other electrode. The serial

circuit of the coil L and the capacitor C now caused a voltage pulse and it was this

pulse that temporarily increased the field intensity between the two filaments G of the

tube light. Combined with the heated state of the filaments, this pulse started an arc

discharge between the two filaments of the tube light. Since a much larger electrical

current now started flowing through the tube light and the coil, the voltage over the

starter dropped to about 160V. The glow discharge tube S was dimensioned in such a

way that this voltage was not sufficient to start a new glow discharge that could bend

the bi-metal again and a steady state was reached as long as the arc discharge

within the tube light was maintained. In case the arc discharge in the tube light was

not ignited in the first cycle, the process in the starter repeated until it did.